Have you ever asked yourself what makes some of your pans non-sticky? The answer is the slippery coating made from polytetrafluoroethylene (PTFE). This revolutionary polymer has various applications, from simple cookware to medical and electrical use.

Yes, PTFE is responsible for your effortless cooking and features in semiconductor parts! So, what is it, what are the applications, and what makes it unique?

What is PTFE?

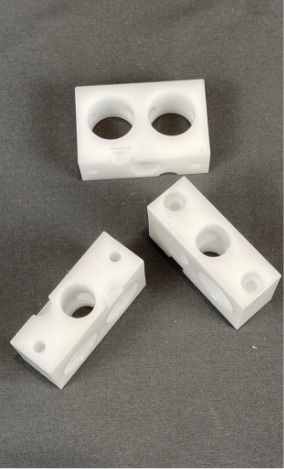

Polytetrafluoroethylene (PTFE), or Teflon, is a high-performance synthetic fluoropolymer of carbon atoms in a chain with two fluorine atoms linked to each carbon atom. This combination creates a unique electronic structure and carbon-fluorine bonds, making it strong, non-reactive to chemicals, etc. As such, the material has found many uses across different industries, including electronics, aerospace, automotive, and cookware.

Advantages of PTFE

PTFE’s properties make it useful in many fields. Here are the advantages it provides.

Thermal Stability

PTFE is highly resistant to temperatures on both ends. The material can withstand high temperatures of 260°C and even +290°C for short periods without degradation. It can also perform very well in cold temperatures of -270°C, making it perfect for use and coating for parts used in extreme temperature conditions.

Chemical and Corrosion Resistance

PTFE is a highly chemically inert material that doesn’t dissolve in any solvent at room temperature. The few chemicals that can corrode PTFE include very hot gaseous fluorine, chlorine trifluoride, alkali metals, and oxygen difluoride. The resistance is easily reinforced with other fluoropolymers, such as PFA.

Electrical Properties

PTFE has a highly symmetric macromolecule structure, giving it a low dielectric constant of 2.0. Furthermore, it has a low dissipation factor and surface resistivity, which provides it with insulating properties against electricity.

Low Friction coefficient

PTFE has a lower coefficient of friction than any other known solid material. It has a static coefficient of 0.08 and a dynamic coefficient of 0.01, making it ideal for areas where little friction is needed. The low friction coefficient also makes it highly resistant to wear.

Anti-adhesion Properties

PTFE has a hydrophobic and oleophobic surface, making it hard to get wet or allow substances to stick. As such, the material shows non-stick properties that make it easy to clean.

Radiation Resistance

PTFE exhibits high radiation resistance without visible degradation up to a dose of 0.02 Mrad.

Other advantages of PTFE include:

- It’s one of the most affordable fluoropolymers

- It is FDA-approved and safe for food manufacturing

What are the Applications of PTFE?

Here are the industries that utilise the properties of PTFE.

Kitchenware Manufacturing

One of the most common applications of PTFE is as a coating in different kitchen appliances and cookware. The non-stick surfaces prevent food from sticking and are easy to clean, making them more efficient in the kitchen. It is used in pots, pans, microwaves, blenders, and coffee makers.

Medical

PTFE has medical-grade properties that make it ideal in medical applications, such as creating medical instruments and testing equipment. It is found in items like sutures, forceps, and catheters. Its high radiation resistance also makes it perfect for blocking radiation leads in X-ray machines.

Automotive

The automotive industry has found many uses for PTFE thanks to its numerous properties. First, the high heat resistance makes it ideal for engine parts that experience high temperatures at high speeds. Secondly, the resistance to chemical corrosion is perfect for dealing with lubricants and fuel. Lastly, PTFE’s low friction is ideal for seals, bearings, and bushings.

Electrical

The high-temperature stability in PTFE makes it a good candidate for use in electronics. It offers insulation for machines that work in extreme weather conditions and parts such as semiconductors and circuit boards. Some manufacturers also combine it with fillers for better electrical and thermal conductivity.

Chemical Processing

The chemical processing and manufacturing industry utilises PTFE for its non-corrosive properties. It is used in making transportation containers and parts that experience the harsh environment of making chemicals. It can remain useful and stable for a long time without damage, ensuring protection throughout the process.

Construction

PTFE provides various advantages to the construction industry. First, the insulating properties make it perfect for insulating the wiring and plumbing. For plumbing, it ensures that the water inside the pipes retains its temperature even when it fluctuates on the outside. It is also used to strengthen some construction tools.

In Summary

Polytetrafluoroethylene has become one of the most used fluoropolymers. It provides properties like high heat, radiation, and chemical resistance, making it ideal for fields. However, its use is strictly controlled to ensure that quality is met.

For all your PTFE inquiries, contact our expert team at Plasticut.