Nylon is a synthetic fiber which has revolutionized the manufacturing industry. It is versatile and widely used. It is a lightweight, durable and inexpensive material which serves as the substitute for other materials because of many benefits that manifests. In this article nylon plastic will be studied including its production way, advantages and disadvantages as well as different applications of the plastic.

What is nylon plastic?

Nylon is a synthetic polymer which is manufactured from coal, water and air. It is one of the types of plastics that are produced from polyamide monomers which are extracted from crude oil commonly called petroleum. This wonderful thing was invented by DuPont Inc. in 1930s and is applicable to numerous spheres due to its unique features. This material, being highly strong, low friction and chemically resistant has been widely chosen in many industries.

How is nylon made?

Nylon is made via polymerization process. By such a mechanism monomers are attached together forming a long chain molecules called polymers. For nylon, the monomers needed are drawn from crude oil by cracking. The monomers are then heated and forced into long chains of repeating segments which are then cooled and chopped into pellets. They are then melted down and extruded (passed through a spinnter (a device with holes) to have long, thin fibers. The fibers are then cooled, stretched and wound onto bobbins which are then used to make all the different nylon products.

Nylon advantages and disadvantages

Advantages of nylon over traditional materials like metal or natural fibers are numerous. Some of its advantages include:

• Less expensive: Comparatively, nylon is immeasurably cheaper than metals like steel and copper. The reason for that is because it is an artificial substance and to fabricate it, little labor is needed contrasted to mining, refining, and processing metal ores.

• Lightweight: Nylon is a very light material thus suitable for applications where the weight is the main thing. Different from the traditional materials steel, nylon could be as low as 75% in weight thus it is an ideal material for instances such as automotive components and aircraft parts.

• Heat resistant: Nylon’s heat resistance is excellent due to it as the idyllic choice for utilization in areas involving high temperatures. It has melting point up to 200°C so can be used in applications like making electric components and cookware.

• Fading resistant: Nylon is more resistant to fading than natural fibers like cotton and wool. This is because it is dyed during the manufacturing process hence the color is more vivid than in other methods of dying. This is the reason why nylon is preferred material for many outdoor products like tents, awnings and furniture simply because of its durability, high strength, weigh reduction, moldability and elasticity.

• Durable: Nylon is a tough and elastic material that can stand a lot of maltreatment. It has a high level of abrasion resistance hence it is suitable for making products such as ropes, tires, and seatbelts which are susceptible to constant friction.

• Custom finishes: Customization of Nylon into different finishes such as matte, glossy or textured is very easy. As such it is the favorite choice for objects that are subject to aesthetic requirements like fashion accessories, sports equipment and toys.

In addition to all the benefits it has, nylon also has some disadvantages. Some of them are:

• Non-biodegradable: Nylon is manufactured material that not biodegradable. After its use, taking hundreds of year to decompose, it becomes the environmental pollutant.

• Prone to static electricity: Nylon is a poor conductor of electricity and its property to carry charges makes nylon prone to static electricity. Hence, some of the applications face issues such as making the electronic items.

Uses of nylon plastic

Nylon is a versatile material which is applied in different industries. Some of its uses include:

• Textiles: Nylon is the leading material in the textile sector due to its endurance and toughness. It is used in the production of many kinds of items which include coat, tents, shoes, bags among others.

• Automotive industry: The automobile industry use nylon in different components such as engine covers, gears, and fuel tanks among others. The material is good when it comes to the lightness and durability which makes it for fuel efficiency in vehicles.

• Electrical components: Nylon is applied in various electrical equipment i.e., plugs, switches and sockets for its heat resistance and insulation abilities.

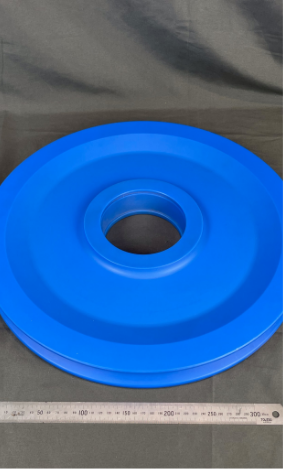

• Industrial applications: Nylon is widely used in the industry due to its huge strength and chemical resistances. It is applied for production of gears / bearings and other parts of machines.

• Packaging materials: Nylon is employed enduring production of packaging products such as the plastic bags and films owing to its high strength and durability.

• Sports equipment: Polyamide or nylon is one of the most broadly used materials for manufacturing different equipment’s of sports for example tennis rackets strings, fishing lines and parachutes owing to its strength and flexibility.

Summary

Nylon plastic is a synthetic material which has found application in a number of fields since its invention in the 1930s. It consists of the long rings of polyamide, which are synthesized from the crude oil and it has many advantages than the traditional ones which is its lightness, high resistance to heat, and durability. Despite of its multiple usages, nylon also has some demerits such as non-biodegradable and likely to get built up static charge. Nevertheless, thanks to its versatility and the properties which are unusual for any material, aluminum is widely used in modern manufacturing.

Plasticut is able to cut-to-size, machine, route and weld to the specifications of our customers. Contact Plasticut today for all your Nylon plastic needs.