PTFE (Polytetrafluoroethylene)

Polytetrafluoroethylene is best known by its commercial application, Teflon. PTFE handles high heat very well without changing its inherent physical properties. It also allows great movement with low friction resistance and is waterproof. As Teflon, PTFE is nowadays used as coating for most non-stick frypans. The use of PTFE plastic material in products is often applied wherever sliding or movement of components is required, such as seals, slide bearings, piston rings, electrical and thermal insulators. PTFE is used widely in plastic cookware and it is even used in the production of the material Gore-Tex.

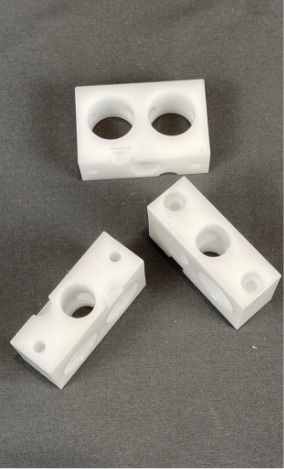

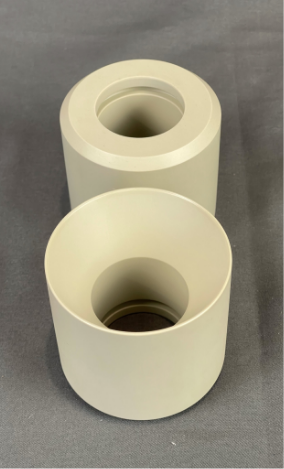

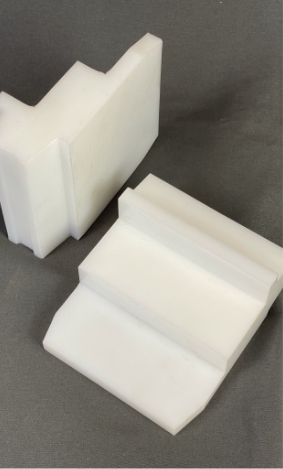

PTFE Work Gallery

PTFE Plastic Properties

- Excellent chemical resistance

- Lowest coefficient of friction

- High operating temperature and stability

- Physiologically inert (virgin)

- Excellent electrical properties

Availability Products

- Sheet

- Rod

- Tube

- Film

- Machined components

PTFE Plastic Products

- Tetron S (Unfilled, natural)

- Tetron G (Higher compressive strength abrasive wear)

- Tetron B (High wear and abrasion resistance, reduced chemical resistance)

- Tetron BR (High wear and creep resistance)

- Tetron C (Highest wear and creep resistance)