CNC Routing

Highly Engineered CNC Routing

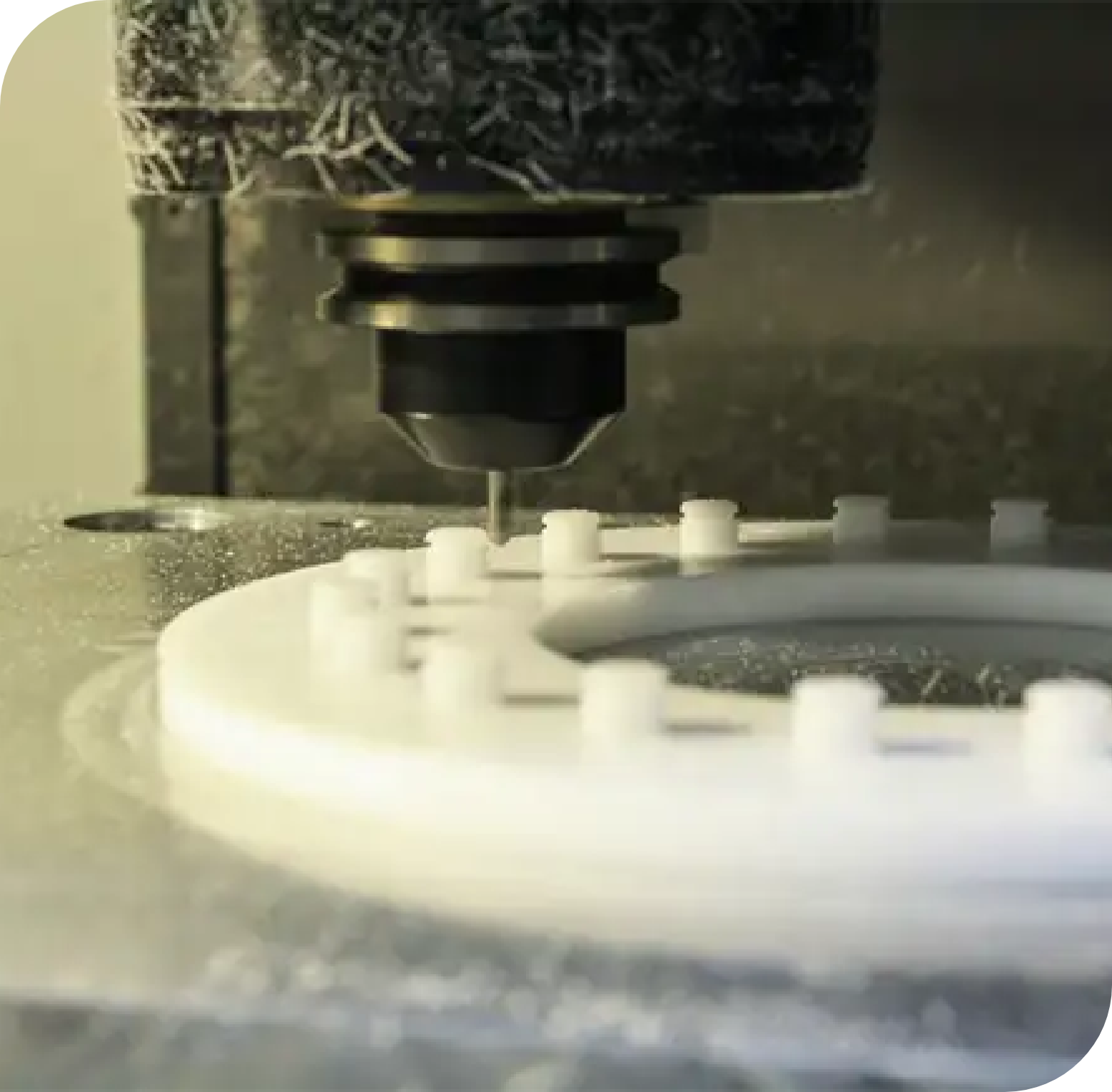

Plasticut specialises in CNC Routing which provides the accuracy and reliability that’s required for high-precision plastic items. CNC Routing produces the exact same results every time, regardless of volume. This level of consistency is essential to our clients who include RMIT, Ford, Tontine and the Australian Department of Defence.

Plasticut manages your project from the concept and design stage right through to fabrication and delivery. We can also provide prototypes, reverse engineer most designs and even work from your notes, sketches or plans.

What is CNC Routing?

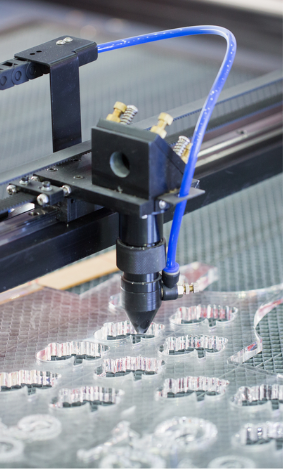

CNC Routing (Computer Numerical Control) is a process that creates complex two three-dimensional parts, quickly, efficiently and safely. Many trades use manual routing machines or power tools with an electric motor that turns a spindle to rout or hollow out areas in hard materials, such as plastic.

Manual routers, however, are unable to provide the precision needed to cut complex two or three-dimensional patterns or designs with multiple surfaces and varying angles in plastics. On the other hand, a computer a controlled router that’s driven by CAD software provides the required precision and consistency.

CNC Routing – Applications

Our advanced CNC Routing machine can cut complex two or three-dimensional designs in a wide range of plastics, including the following.

- Advanced Engineering Plastic.

- Polyethylene.

- Polypropylene.

- Polycarbonate.

- Polyurethane.

- Acetal.

- Nylons.

- PETP.

- PTFE.

- PVC.

- Acrylic

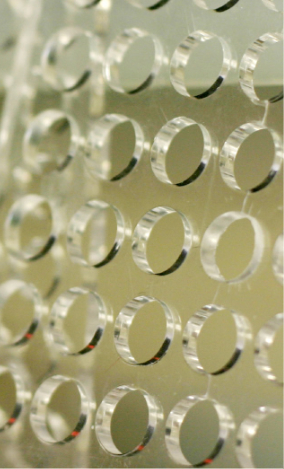

When you need uniform and precise parts with incredible tolerances, then CNC Routing is your best option. We can produce small quantities or large volumes of products, even prototypes can be produced for new projects. Routed plastics are used in thousands of applications, from lighting fixtures, retail displays and signage to architectural features, medical devices, engineering components, pipe couplings, pumps, pipes and fittings and the list goes on.

CNC Routing creates parts or completed items by drilling, turning or milling a range of plastics. Since the process is directed by computer software, the resulting parts or completed items are accurate, precise and consistent. Whether you want one prototype or 10, 000 items, each will be an exact uniform copy of the original design.

CNC Routing is known for its fast turnaround times, tight tolerances, uniform parts and cost savings. The latter is because the precise cuts reduce wastage, leading to savings and higher profit margins. Since most of the operations are computer driven, there’s less need for labour which also reduces costs.

CNC Routing can be used on a wide range of plastics and once the design has been entered into the computer, it will continue to create the parts, until the order is complete.

- Minimum wastage.

- Highly precise and accurate cuts.

- Tight tolerances.

- Consistent and uniform parts.

- Cuts a wide range of plastics.

- Fast turnaround times.

- Cost-effective.

Plasticut is an Australian-owned and operated plastic manufacturing company, offering a range of services that includes CNC Routing. Whether a single prototype or thousands of parts or components, we can design, cut and deliver anywhere in Australia and around the world.

To find out if CNC Routing is suitable for your parts or components, contact the team on 03 9357 6688 or send us an email enquiry.

- Australian-owned and operated company.

- More than 40 years in the industry.

- Latest technology in fabrication and design.

- Large stock of plastics onsite.

- Wide network of suppliers.

- Fast and efficient service.

- Short turnaround times.

- Friendly customer service.

- State-of-the-art workshop.

- Obligation-free quotes.

To find out if CNC Routing is suitable for your parts or components, contact the team on 03 9357 6688 or send us an email enquiry.