CNC Machining

CNC machining services – Melbourne

Plasticut is one of the leading providers of CNC machining services in Melbourne. We specialise in CNC milling and CNC turning to create high quality components across a wide range of industries. From single prototypes to small batch components or large scale productions, Plasticut has the expertise and capacity to deliver your order, quickly and efficiently.

One of the attractions of CNC machining in Australia is that once the design is set, it can manufacture as many replicates as required. It’s also a method that’s well suited to creating precision prototypes or complex designs. Applications include medical devices, food service equipment, communication devices, weapons, electronics, and automotive and aerospace parts.

Other benefits of our CNC machining services include tight tolerances, fast turnaround times and affordability.

What is CNC machining?

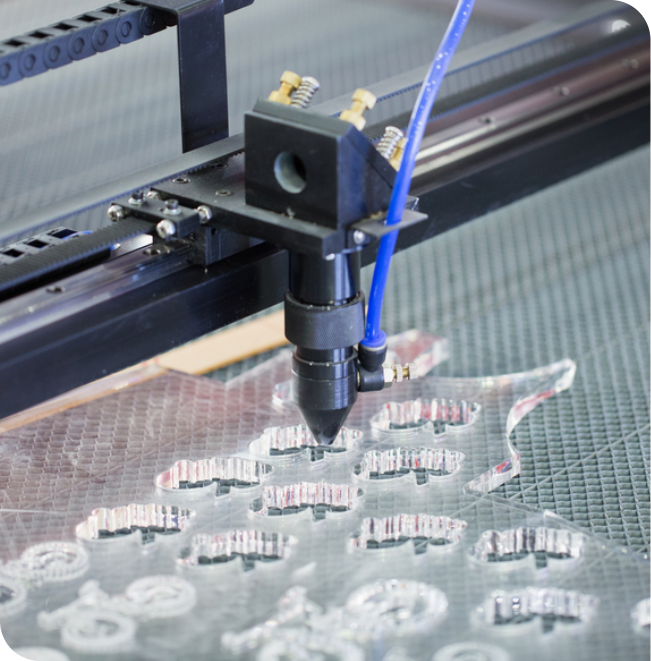

CNC machining is a computerised process that uses pre-programmed software to control the actions of complex machinery. It’s used to create highly precise plastic components or products across a variety of industries.

The term “CNC” actually means Computer Numerical Control and simply refers to the automated control of machine tools, including CNC lathes, turning and milling equipment. In simpler terms, it combines mechanical designs, technical drawings, mathematics and computer programming to produce a range of plastic parts and components. Essentially, using CNC machining, we can take a sheet of plastic and create a complex and highly precise aerospace or automotive component.

CNC machine programming

The computerised process controls all the movements and measurements of the design, including the feed rate of the plastic sheeting and the location and speed of the cuts. The dimensions of the finished parts are controlled using CAD (computer-aided design) software whilst the logistics of the manufacturing processes are controlled by the CAM (computer-aided manufacturing) software.

Once pre-programmed, the machinery continues to operate until the order is completed with little human involvement. This software is the heart of a process that results in highly precise and complex parts with extremely low tolerances.

You can select from a range of plastic materials that are suitable for CNC machining, as follows:

- Polyethylene

- Acetal

- Nylons

- PETP

- Polypropylene

- PTFE

- PVC

- Advanced Engineered Plastic

- Polycarbonate

- Acrylic

Plasticut offers high-quality CNC machining services that include CNC milling and CNC turning. Whilst these two services might seem similar and of course, there are some similarities between these techniques, they are used to create different types of components or parts.

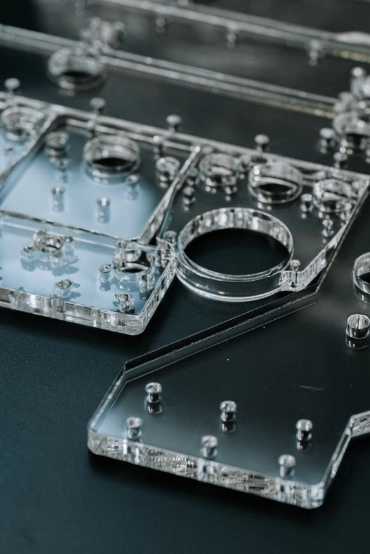

CNC milling is a machine process that manufactures parts by gradually removing elements of the base material using rotating, multi-point cutting tools. CNC milling requires that the plastic material itself is rotated while the cutting tools remain stationary. The carousel contains up to thirty tools, ensuring that the vast majority of milling jobs can be completed in one set-up.

CNC milling can be used to machine shapes that are not round, symmetrical or cylindrical, such as square or rectangular. This process is particularly useful for creating bevels, angles, slots and other complex designs. It’s a technique that lends itself well to small production runs or prototyping.

CNC turning is a process that uses a CNC lathe to remove a pattern of material that results in the required design. Unlike CNC milling, however, the CNC lathe holds a bar of plastic material stationary in a chuck that’s attached to a spindle that is spun at high speed. At the same time, a single-point tool moves along the longitudinal axis of the bar to shave away material and create highly precise cylindrical cuts.

It’s a technique that creates custom parts using an old technique – the lathe – and updates it to the latest technology. The result is a CNC lathe that’s driven by computer software and is generally used to create cylindrical shaped components or parts. CNC turning is the best option if you want to produce cylindrical or radial-shaped parts quickly and in high volume. Whether CNC milling or CNC turning is best for your project is determined by the shape, size, volume and required finish of the components, as well as the project’s budget.

Plasticut is one of the leading providers of CNC machining in Australia. We can help with everything from the design stage to the finished product. If you don’t have a design, then a photo, sketch or even an idea will do!

Our incredibly talented and skilled technicians are happy to collaborate with you to create the parts, components or finished product you require for your project. If you can’t decide whether CNC milling or CNC turning is best for your project, then based on the application, we can provide all the advice you need to make an informed decision.

If you have an idea or design in mind, then don’t hesitate to call us and speak to one of our technical experts. We’ll discuss your ideas and the outcome you hope to achieve, fine-tuning your design and adding more details to develop a concept that suits your needs.

On the other hand, if you already have a firm design in mind, we’ll head straight to discussing the best type of plastic and the CNC machining techniques required to give you the result you desire. We’ll also talk about turnaround times, shipping and your project’s budget. Simply give us a call to get the ball rolling!

With more than 40 years in the plastic fabrication industry, Plasticut has become one of the leading providers of CNC machining services. If you want to create prototypes or need a small production run, then talk to our expert team about CNC machining!

- More than 40 years in the industry.

- Family-operated and Australian-owned company.

- Latest CNC milling and turning equipment.

- Wide network of suppliers.

- Fast turnaround times.

- Affordable prices.

- Friendly customer service.

- Obligation-free quotes.

- Large stock of plastics available.

For more information on our CNC machining services in Melbourne, contact the team on 03 9357 6688 or send us an email enquiry.